OEM DC brushless motor-TH152 introduction

TH152 adopts high transparent engineering plastic front cover, easy to observe the running condition; The shell is streamlined with special coating on the surface for easy cleaning. Open the cover to stop the function, to ensure safe operation; Automatic alarm function when abnormal work; The roller assembly has a manual rocker, which can be manually operated with the adaptive clamping device, facilitating the loading and unloading of the hose; Spring roller assembly, can prevent hose overpressure caused by hose rupture, reduce hose wear and improve hose service life; Maintenance-free DC servo motor, closed loop control, silent operation.

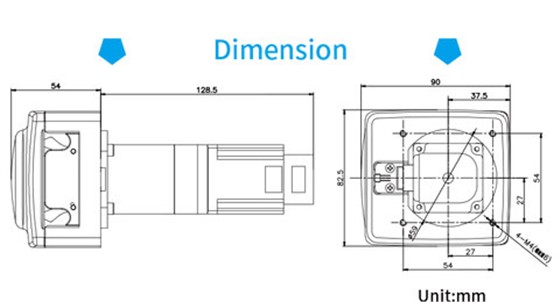

OEM DC brushless motor-TH152 Dimension

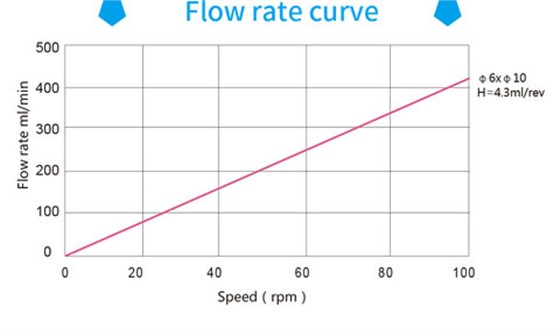

OEM DC brushless motor-TH152 Flow Curve

Features and benefits

- • The pump head uses the streamlined casting with special coating, the housing covered with telfon, the pump cover usethe high transparent PC material.

- • Spring roller assembly efficiently decreases tubing abrasion, maintain exit pressure from 0-1.5 bar, pump head spring reduce pressure avoid fluid erupting.

- • Low noise, IMS planetary gear reducer imported from Germany, low noise and long life

- • Servo control, speed, torque, closed loop control, speed running smoothly, precise control, torque could adjust according to the load change.

- • Low heat, servo control brushless motor, flow rate change accordingly, the temperate below 39C

- • RS232 communication, ModBus RTU communication protocol control start, stop and rotation speed

Technical summary

| Product selection | |

| Configuration | TH152 Pumphead+DC servo motor with IMS gear box+Drive |

| Motor consits of 42 DC servo motor and Iws gear box+Drive | |

| Dimension | Pump head 82.5*90*50.5 |

| Flow rate | 0-430m/min |

| Operating noise< | < 55dB |

| Cotrol | Communication pocol: Modbus RTUPort: R5232 Baud Rate: 38400 |

| Tubing | Φ6.5*Φ10 |