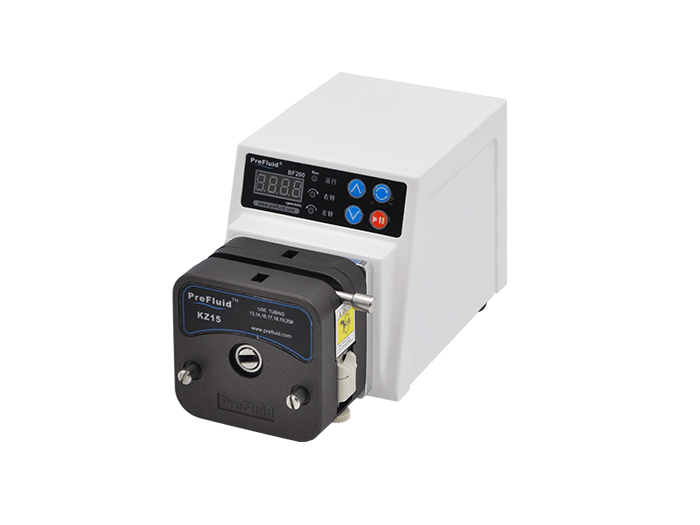

Peristaltic pump is a new type of industrial pumps, more and more industries, the use of peristaltic pumps in the liquid transfer more and more cases, here Pratt peristaltic pump manufacturers to share with you, peristaltic pumps in the pulse is what? Why reduce the pulse?

What is the pulse?

Because the peristaltic pump is through the rotor on the elastic hose for alternately squeezing and releasing to transport fluids, so the transmission of fluids will be a strand of outflow, the phenomenon of this transmission of liquid is the pulse.

How to minimize pulsation?

1. Use a pulse damper

This device, is the use of air compression principle to absorb the pulse, but also to eliminate the pipeline pulse of the commonly used components, not only peristaltic pumps, other pumps generated by the operation of the pulse will also use the pulse damper.

2. Increase the number of rollers

Since the pulse is due to the rotor on the hose extrusion formation, then increase the number of rotors can be, with, for example, 10 rotors of the pump head when the pulse generated by the operation is already very low. Note, however, that with more rotors, the flow rate will be lower.

What is pulsation and how to reduce pulsation in peristaltic pumps?

3. Use a double head with an offset roller.

Part of the pump head can be installed two hoses, the use of running cross on the tube extrusion, the two tubes generated by the pulse to complement can effectively reduce the pulse.

4. Add discharge tubing.

Tubes will absorb pulses, especially softer tubes such as silicone due to friction, longer discharge tubes will also increase back pressure. This tends to compress the pulses together. This will reduce the pulses by up to 60%.