Peristaltic pump is a special type of pump, which has a unique working principle and a wide range of application fields. This article will introduce the definition, principle, structure and advantages of peristaltic pump in detail, and explore its application cases in different industries.

Definition of peristaltic pump

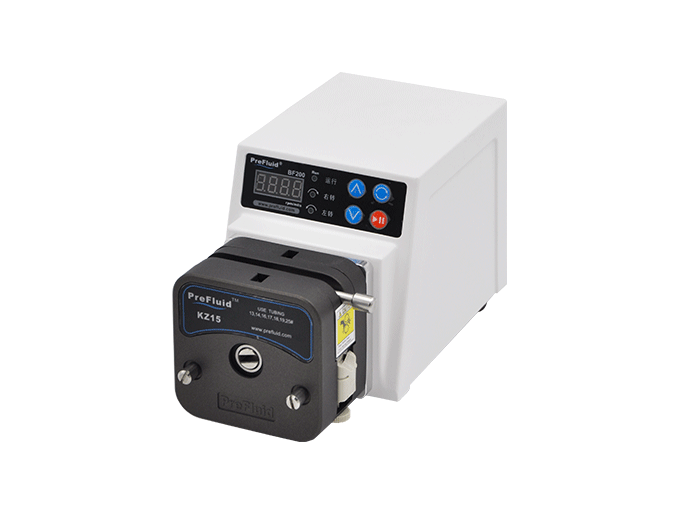

Peristaltic pump is also known as peristaltic mixing pump or rubber mixing pump, it is a kind of equipment through the peristaltic extrusion of rubber tube to achieve liquid transportation. Its name comes from its working principle, that is, peristalsis, which can also be figuratively understood as "worm-like" movement.

Peristaltic pump is suitable for all kinds of liquid transportation, whether it is high viscosity, easy corrosion or containing particles and other special liquids, can be effectively transported through peristaltic pump. The main feature of peristaltic pump is that it can be efficiently transported under low speed and large flow condition, and the agitation and shear force of the transported liquid is small.

Second, the working principle of peristaltic pump

The working principle of peristaltic pumps is based on peristaltic extrusion and valve plugging. It consists of a driving device and a rubber tube. The driving device squeezes the rubber tube through a connecting rod or pressure tank to push the liquid in the rubber tube forward.

When the liquid passes through the rubber tube, the rubber tube is squeezed, creating a sealed cross-section that pushes the liquid forward. Then, when the liquid passes through the rubber tube, the rubber tube immediately returns to its original state, forming a negative pressure area, thereby inhaling the next part of the liquid. This cyclic extrusion and recovery process allows the liquid to be continuously pushed and transported.

Third, the structure of peristaltic pump

Peristaltic pump usually consists of a driving device, rubber tube, valve and control system.

1. Driving device: The driving device is the core part of the peristaltic pump, which provides pressure through the connecting rod or pressure tank, so that the rubber tube can be squeezed.

2. Rubber tube: Rubber tube is a key component of peristaltic pump, it is responsible for liquid propulsion and inhalation. Rubber tubes have high elasticity and wear resistance, and can withstand long periods of extrusion and recovery.

3. Valve: The valve is used to control the flow direction and pressure of the liquid to ensure that the liquid is transported on demand. Common valve types include check valves, peristaltic valves, etc.

4. Control system: The control system is used to monitor and control the operating state of the peristaltic pump, which can achieve automatic control and adjustment.

Fourth, the advantages of peristaltic pump

Peristaltic pumps have many unique advantages over other types of pumps, making them widely used in various industries.

1. Efficient transport: peristaltic pump can achieve efficient liquid transport under the condition of low speed and large flow, which greatly improves work efficiency.

2. Strong adaptability: peristaltic pump is suitable for all kinds of liquid transportation, including special liquids such as high viscosity, containing particles and easy corrosion.

3. No leakage: Due to the working principle of the peristaltic pump, the liquid will not leak during the transportation process, ensuring safety and environmental protection.

4. Energy saving and environmental protection: The energy required by the peristaltic pump is relatively low when working, so it can save energy and reduce the impact on the environment.

5. Application cases of peristaltic pump

Peristaltic pumps are widely used in many industries, mainly including chemical, pharmaceutical, food and beverage, sewage treatment and so on.

1. Chemical industry: peristaltic pumps are often used to transport various types of chemical liquids, such as acids, alkalis, solvents and so on. Its efficient transport and leak-free characteristics make it an ideal choice for the chemical industry.

2. Pharmaceutical industry: peristaltic pump plays an important role in the pharmaceutical process, and can be used to transport drugs, apis, preparations, etc., while ensuring the purity and safety of drugs.

3. Food and beverage industry: Because the peristaltic pump has a small shear force on food liquid and can maintain the quality of liquid, it is widely used in the food and beverage industry to transport juice, berries and so on.

4. Sewage treatment industry: peristaltic pump can effectively transport sewage containing solid particles in the sewage treatment process, and reduce the cost of sewage treatment through its efficient transportation and no leakage characteristics.

In summary, "What is peristaltic pump" is a detailed introduction to peristaltic pump. From the definition, working principle, structure and advantages of peristaltic pumps to application cases, we hope to establish a comprehensive understanding of peristaltic pumps. Peristaltic pump has many advantages such as efficient transportation, strong adaptability, no leakage, energy saving and environmental protection, and has a wide range of applications in chemical, pharmaceutical, food and beverage and sewage treatment industries. Through the elaboration of this article, I believe the reader has a deeper understanding of the peristaltic pump.