In the field of filling, peristaltic pump is a common equipment, which is widely used in various industries. The speed of the peristaltic pump plays a crucial role in the filling process. This paper will discuss the role of filling peristaltic pump speed, and how to adjust the speed reasonably, in order to achieve the best filling effect.

In the field of filling, peristaltic pump is a common equipment, which is widely used in various industries. The speed of the peristaltic pump plays a crucial role in the filling process. This paper will discuss the role of filling peristaltic pump speed, and how to adjust the speed reasonably, in order to achieve the best filling effect.

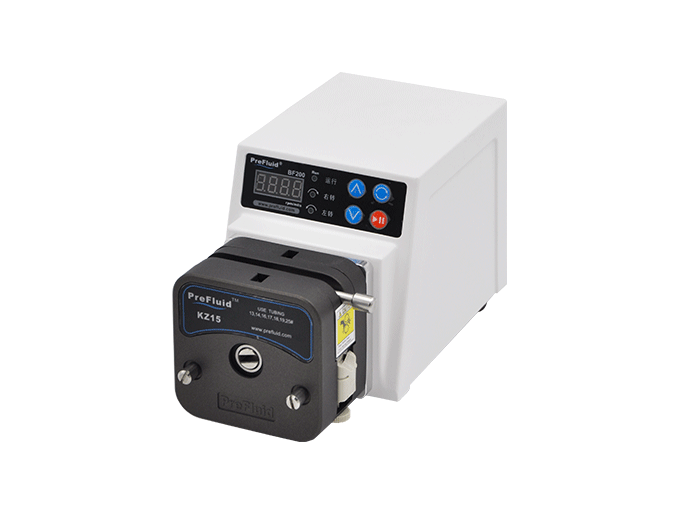

First of all, understanding the working principle of peristaltic pumps is crucial for us to understand the role of their speed. The peristaltic pump compresses and releases the medium in the pump chamber through the peristaltic wheel in the pump shell, so as to achieve the purpose of pumping. The rotational speed of the peristaltic pump determines the movement speed of the peristaltic wheel in the pump shell, and then affects the flow and pressure of the pumping medium.

In the filling process, the rotational speed of the peristaltic pump directly affects the filling speed and filling accuracy. Too low speed will lead to too slow pumping speed, affecting production efficiency; If the speed is too high, the pumping speed will be too fast, which is easy to cause leakage and waste in the filling process. Therefore, the reasonable adjustment of the rotational speed of the peristaltic pump is very important to achieve an efficient and accurate filling process.

In addition to the impact on the filling speed and accuracy, the rotational speed of the peristaltic pump will also affect the flow characteristics of the medium during the filling process. When the speed is too low, the flow rate of the medium is slow, and blockage or accumulation may occur; When the speed is too high, the medium flow rate is too fast, which is easy to cause shear damage and bubble generation. Therefore, adjusting the rotational speed of the peristaltic pump so that the medium can pass through the pump chamber at a reasonable flow rate is an important link to ensure the filling quality.

In the actual filling production, according to different product characteristics and filling requirements, it is necessary to choose the rotational speed of the peristaltic pump reasonably. Generally speaking, when filling products with higher viscosity, the speed can be appropriately increased to increase the flow rate and ensure the smooth medium; When filling products with low viscosity, the speed can be appropriately reduced to reduce the risk of spills. At the same time, through continuous practice and adjustment, to find the best speed range, you can improve production efficiency and filling quality.

In addition to the adjustment of speed, there are some other factors that will also have an impact on the operation of the peristaltic pump. For example, the compatibility of the pump chamber with the medium, the size and material of the pump chamber, and the service life of the pump chamber. These factors are related to the speed and need to be considered comprehensively in actual operation.

In summary, the reasonable adjustment of the rotational speed of the filling peristaltic pump is crucial to achieve an efficient and accurate filling process. By understanding and mastering the working principle of peristaltic pump, combined with actual production needs, reasonable selection of speed, and continuous adjustment and optimization, can improve production efficiency, reduce costs and ensure the quality of filling.