Peristaltic pump metering is a type of pump equipment used to accurately transport liquids, and is often referred to as peristaltic pump metering devices. Its main principle is that through the squeezing action of peristaltic pump, the liquid produces peristaltic movement in the peristaltic pump pipe, and reaches the precise conveying volume in a certain period of time.

Peristaltic pump has the characteristics of fast and comfortable operation of molecular pump, and because of its unique design structure, it is also widely used in medical, chemical, food, pharmaceutical and other fields.

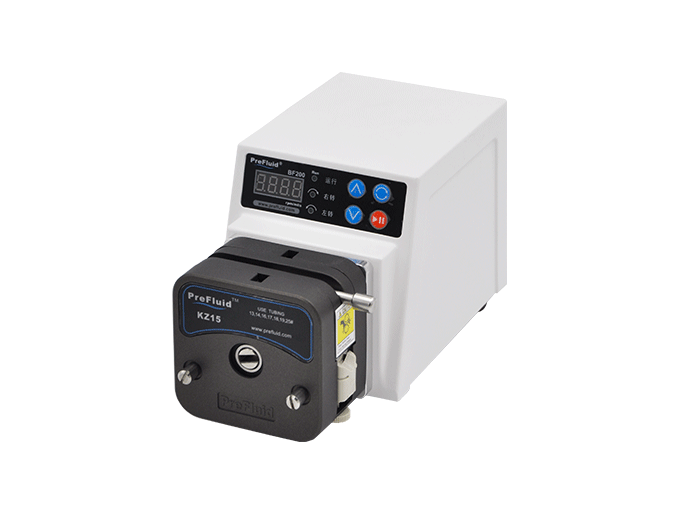

The working principle of peristaltic pump is to compress the peristaltic tube on the outer wall of the pump shell and squeeze the liquid in it to push it to the outlet. The peristaltic pump is usually composed of a driving device, a pump housing, a peristaltic tube and a control system. The driving device is usually an electric motor that can provide enough energy to drive the pump body to do the work. The pump housing provides a stable working platform for mounting the drive and other necessary components. Peristaltic tube is the core component of peristaltic pump, usually made of soft rubber or plastic. The compression and release of the peristaltic tube allows the fluid to be delivered precisely to the specified location. The control system is used to control the speed of the pump, the delivery volume, and other parameters and functions.

The peristaltic pump quantitative working process is very accurate and reliable. Through reasonable control system Settings, the running speed and conveying volume of the pump can be accurately adjusted to meet the requirements of different process conditions. In addition, the peristaltic pump also has the advantages of self-priming, corrosion resistance, no leakage, etc., and can be applied to the transportation of a variety of liquids, such as chemical raw materials, pharmaceutical liquids, food additives, etc.

Peristaltic pump quantification has been widely used in medical field. Many processes in the medical field require precise fluid delivery, such as drug formulation, infusion, hemodialysis, etc. Peristaltic pump metering can meet these needs, and the peristaltic tube material it uses meets the sanitary standards of medical devices, helping to ensure that the liquid delivered is pure and sterile.

The chemical industry is also one of the important application areas of peristaltic pump quantification. In the process of chemical production, for some toxic and harmful chemicals, it is very important to accurately control the delivery volume and flow rate. The peristaltic pump has good corrosion resistance and can safely transport these chemicals, avoiding the risk of leakage and contamination.

Precise liquid formulation and dosage control are also critical in the food and pharmaceutical industries. The peristaltic pump quantification can not only meet these needs, but also its material and liquid contact parts are made of food grade or medical grade materials, which meet the relevant health standards, fully ensuring the safety and reliability of the product.

In short, as a kind of pump equipment for accurate liquid transportation, peristaltic pump has a wide range of application prospects in medical, chemical, food, pharmaceutical and other fields. Its advantages of accuracy, reliability and corrosion resistance make it an indispensable industrial equipment in many industries. With the continuous development of science and technology, peristaltic pump quantitative is also constantly updated and innovative to meet the changing market demand.