In industrial production, liquid transportation has always been a key link. In high-flow industrial scenarios, it is particularly important to choose an efficient and reliable pumping station. In this field, the large flow industrial peristaltic pump has undoubtedly become the first choice for many enterprises, because its unique technical advantages can meet the needs of users.

In industrial production, liquid transportation has always been a key link. In high-flow industrial scenarios, it is particularly important to choose an efficient and reliable pumping station. In this field, the large flow industrial peristaltic pump has undoubtedly become the first choice for many enterprises, because its unique technical advantages can meet the needs of users.

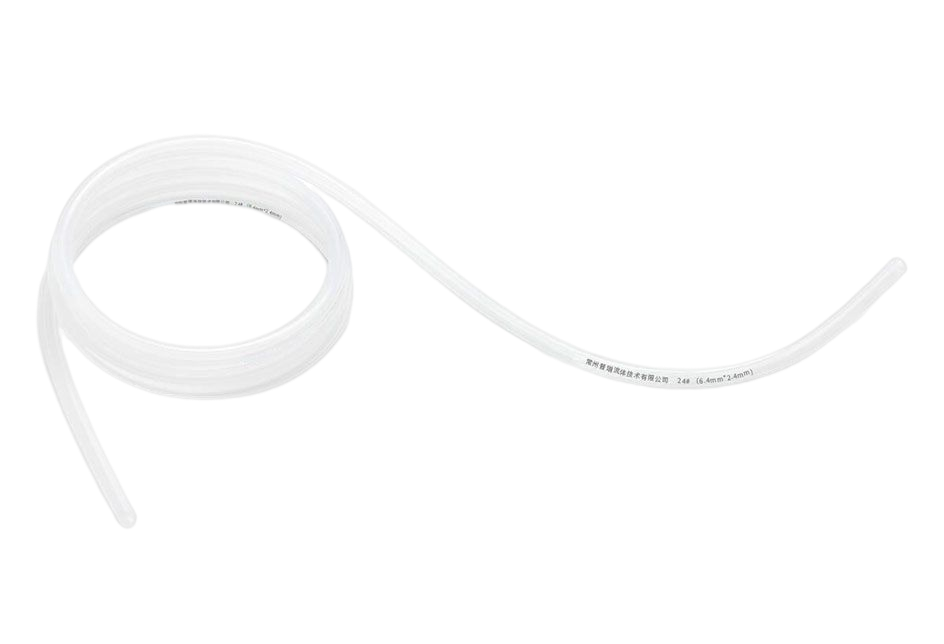

The large flow industrial peristaltic pump uses the peristaltic principle to compress and release the hose to smoothly transport the fluid to the target position. Compared with traditional pump technology, peristaltic pumps have many advantages. The first is its high reliability, because the hose is the only part in contact with the medium, so it does not produce any secondary pollution to the medium. The second is its excellent self-priming ability, even under a long suction, the peristaltic pump can achieve rapid start and maintain continuous operation. In addition, it can also handle special conditions such as high concentration, high viscosity, high solid content and easy volatiles. These characteristics of large flow industrial peristaltic pumps make them widely used in chemical, environmental protection, pharmaceutical, food and beverage industries.

Compared with traditional pumps, large flow industrial peristaltic pumps are easier to operate and maintain. Since the peristaltic pump has no mechanical seal, no additional coolant is required, greatly reducing maintenance costs and repair time. In addition, noise during operation is also effectively controlled, creating a better office environment for staff.

For high flow requirements, peristaltic pumps extend the functionality of piping, control systems and software. It can be connected with other devices through intelligent control systems to achieve remote control and fault monitoring, helping enterprises to achieve automated management and improve production efficiency. At the same time, according to the needs of users, multi-pump parallel, automatic reversing, automatic emptying and other functions can be realized to meet the needs of special working conditions.

Large flow industrial peristaltic pumps have not only made breakthroughs in performance, but also contributed to energy conservation and environmental protection. Its valveless design ensures a stable transmission flow and avoids energy waste. At the same time, the hose material used by the peristaltic pump is also in line with environmental standards and will not cause pollution to the environment. This feature of energy saving and environmental protection can not only reduce the operating costs of enterprises, but also enhance the image of enterprises and better meet the needs of sustainable development.

In summary, large flow industrial peristaltic pump with its unique technical advantages and good adaptability, has become the ideal pump station selected by most enterprises. No matter which part of industrial production, it can quickly and stably complete the task of liquid transportation. It is believed that with the continuous progress of science and technology, large flow industrial peristaltic pumps will usher in a broader application space in the future.