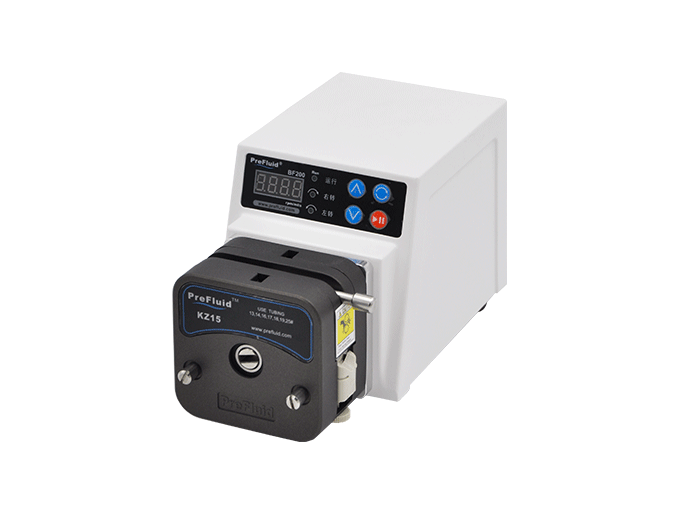

Double channel peristaltic pump is an advanced conveying equipment, which is widely used in chemical, pharmaceutical, food, environmental protection and other fields. In this paper, the working principle, structural characteristics, application fields, selection and maintenance of the double channel peristaltic pump are introduced in detail.

Double channel peristaltic pump is an advanced conveying equipment, which is widely used in chemical, pharmaceutical, food, environmental protection and other fields. In this paper, the working principle, structural characteristics, application fields, selection and maintenance of the double channel peristaltic pump are introduced in detail.

1. How it works

The two-channel peristaltic pump adopts the principle of peristaltic motion to realize fluid transport. Through the mutual compression of the wave wheel and the peristaltic wheel placed in the pump body, the elastic rubber tube produces peristaltic movement with the rotation of the wave wheel and the peristaltic wheel, so as to achieve the forward or reverse transmission of fluid. The working principle of the peristaltic pump is simple and reliable, without the use of mechanical seals, and can effectively avoid leakage problems.

2. Structural characteristics

The pump body of the two-channel peristaltic pump is usually made of stainless steel or cast iron material, which has strong pressure and corrosion resistance. The wave wheel and peristaltic wheel installed in the pump body are made of high-strength materials and can withstand greater pressure and wear. The pipeline system of peristaltic pump is composed of elastic rubber pipe and pipe clamp, which is easy to install and replace. At the same time, the double channel peristaltic pump also has the characteristics of small volume, low noise, easy maintenance and so on.

3. Application field

Two-channel peristaltic pumps are widely used in chemical industry to transport a variety of corrosive, viscous and high-temperature liquids. It can transport sulfuric acid, hydrochloric acid, hydrofluoric acid and other strong acids, as well as lye, organic solvents and other chemicals. In the pharmaceutical industry, the double channel peristaltic pump can be used to transport various pharmaceutical agents, slurries, suspensions and so on. In addition, the pump can also be widely used in food, beverage, environmental protection and other fields of liquid transportation and treatment process.

4. Select and maintain

The choice of suitable two-channel peristaltic pump should consider the flow rate, pressure, medium properties and other factors. In the selection, the performance parameters of the pump, working conditions, the use of the environment and other factors should be considered comprehensively to ensure the efficiency and safety of the pump. In addition, in the process of use and maintenance, it is necessary to regularly check the wear of the pump body, pipelines and rubber pipes, and replace the parts with serious wear in time to extend the service life of the pump.

In summary, double-channel peristaltic pump, as an advanced conveying equipment, has a wide range of application prospects in chemical, pharmaceutical, food, environmental protection and other industries. Its simple and reliable working principle, superior structural characteristics and ability to apply to a variety of media make it an important choice in the field of liquid transportation. When selecting and using the two-channel peristaltic pump, it is necessary to make a reasonable choice according to the actual needs, and strengthen the maintenance of the pump to ensure its long-term stable operation.