Traditional fluid transport methods are often limited by pipeline layout, transport distance and transport medium and other factors, while the basic peristaltic pump has become a highly efficient fluid transport solution with its unique advantages. Whether in the chemical, food, pharmaceutical or environmental protection industries, the basic peristaltic pump has shown excellent performance and has become an indispensable equipment.

Traditional fluid transport methods are often limited by pipeline layout, transport distance and transport medium and other factors, while the basic peristaltic pump has become a highly efficient fluid transport solution with its unique advantages. Whether in the chemical, food, pharmaceutical or environmental protection industries, the basic peristaltic pump has shown excellent performance and has become an indispensable equipment.

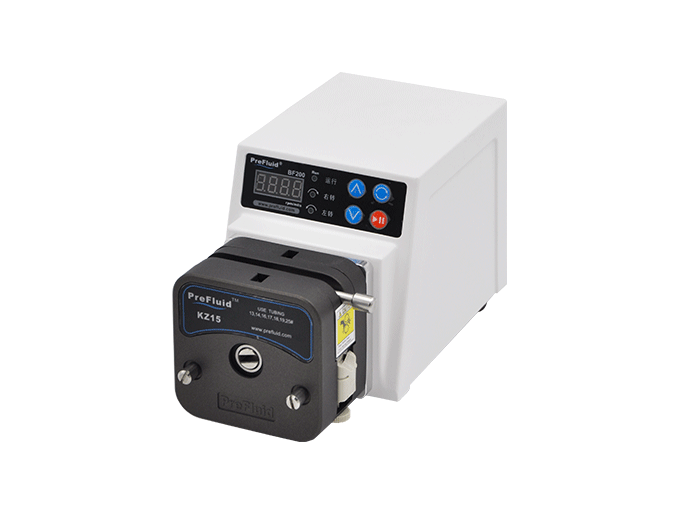

The working principle of the basic peristaltic pump is very simple, which realizes the transport of fluid through the axial compression of the flexible pipe. When the motor drives the compression device to rotate, the flexible pipe is squeezed and deformed, resulting in a continuous and rhythmic wriggling effect that pushes the fluid to the target position. This design not only enables precise flow control, but also resizes special conditions such as high pressure and corrosion.

The basic peristaltic pump has several advantages, the first being its high-precision flow control capability. By controlling the speed of the motor and the structure of the extrusion device, the flow of fluid can be precisely adjusted to meet different process requirements. Secondly, the flexible pipe of the peristaltic pump can adapt to the transportation of various media, such as solid particles, high-viscosity liquids, etc., to ensure that the transportation process will not clog or leak. In addition, the basic peristaltic pump also has the characteristics of low shear force, low vibration and low noise, which effectively protects the quality and stability of the conveying medium.

The basic peristaltic pump has a wide range of applications in many industries. In the chemical industry, it can be used to transport various chemicals, solutions and wastewater; In the food industry, it can be used to transport jam, soy sauce, milk and other liquids; In the pharmaceutical industry, it can be used to transport pharmaceutical liquid, pharmaceutical pulp and biological products; In the environmental protection industry, it can be used to transport waste water, waste liquid and sludge. The basic peristaltic pump has a wide range of applications, which can meet the needs of all walks of life for fluid transportation.

In addition to the above advantages and applications, the basic peristaltic pump also has the characteristics of simple maintenance, energy saving and environmental protection, and high cost effectiveness. Compared with traditional fluid delivery methods, the basic peristaltic pump requires no additional supplies and has lower maintenance costs. Its high efficiency and energy saving characteristics also meet the sustainable development needs of modern enterprises.

When choosing the basic peristaltic pump, it is necessary to pay attention to select the appropriate model and specifications according to actual needs to ensure its normal operation and service life. In addition, regular maintenance and maintenance is also the key to ensure the performance of peristaltic pumps, and attention needs to be paid to timely replacement of flexible pipes, cleaning filters and checking seals.

In short, the basic peristaltic pump with its high-precision flow control, adaptable transport medium and easy maintenance characteristics, become the ideal solution in the field of fluid transport. Whether it is in the chemical, food, pharmaceutical or environmental protection industries, the basic peristaltic pump can play its unique advantages and provide strong support for the production and development of enterprises.