Peristaltic pump is a commonly used fluid conveying equipment, and its accuracy plays an important role in the stability and accuracy of fluid conveying. This article will explore the accuracy of peristaltic pump, including its principle, influencing factors and how to improve the accuracy, so that you have a comprehensive and in-depth understanding of the accuracy of peristaltic pump.

The working principle of peristaltic pump is to drive the contraction and peristalsis of the hose or pipe through the pressure change, so as to achieve the delivery of fluid. The accuracy of peristaltic pump is mainly reflected in the accuracy and stability of flow. Specifically, the accuracy of the peristaltic pump is affected by the following aspects.

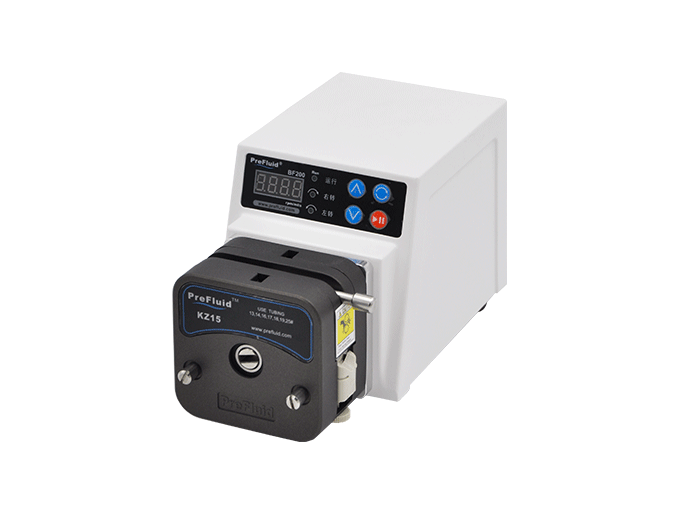

First of all, the design and manufacturing quality of peristaltic pumps have a direct impact on accuracy. High-quality peristaltic pumps should use precision processing technology and high-quality materials to ensure the tightness and coordination of the pump head and hose. In addition, the structure and parameter design of peristaltic pumps also need to consider fluid properties, flow requirements and other factors to improve accuracy.

Secondly, the material and use status of the hose have an important impact on the accuracy of the peristaltic pump. Hose is an important part of peristaltic pump, and its elasticity and wear resistance are directly related to the accuracy of the pump. The appropriate hose material should have a high elastic recovery rate and wear resistance to maintain the accuracy of fluid delivery. In addition, the use time and use state of the hose will also affect the accuracy, so regular replacement and maintenance of the hose is one of the important measures to improve the accuracy of the peristaltic pump.

In addition, the nature of the fluid and the parameters of the pump head will also affect the accuracy of the peristaltic pump. Different fluids have different viscosity and flow properties, which challenges the accuracy of peristaltic pumps. Therefore, for different fluids, choosing the appropriate hose material and adjusting the parameters of the pump head are the key to improve the accuracy. In addition, reasonable pipe layout and pipe resistance control can also improve the accuracy of peristaltic pump.

In addition, the technical level and maintenance of the operator will also directly affect the accuracy of the peristaltic pump. Operators should be familiar with the working principles and operating procedures of peristaltic pumps, and carry out regular maintenance work. Timely inspection and replacement of worn parts, adjustment and calibration of pump head parameters, and maintenance of hose elasticity are all important links to improve the accuracy of peristaltic pumps.

In general, the accuracy of peristaltic pumps is crucial for fluid delivery. By strengthening the understanding of the principle of peristaltic pump, selecting high-quality peristaltic pump and hose materials, combined with reasonable pipeline layout and operation and maintenance, the precision of peristaltic pump can be effectively improved to ensure the accuracy and stability of fluid transport.