Peristaltic pump speed refers to the relationship between the rotational speed of the pump head and the flow of the conveying medium when the peristaltic pump is working. In many industrial fields, peristaltic pump is an important conveying device, and its speed control is of great significance to achieve accurate flow regulation and operation safety. This paper will introduce the principle and application of peristaltic pump speed control in detail.

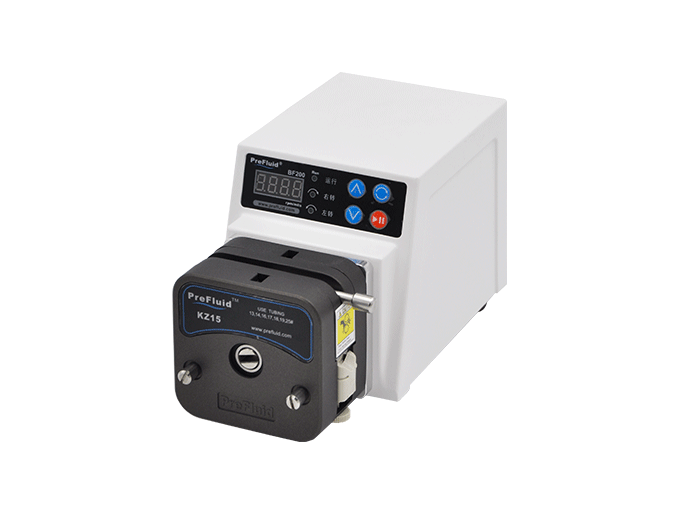

Peristaltic pump is a kind of pump equipment with many advantages. It adopts the way of roller extrusion pipeline to realize the transportation of medium. The control of peristaltic pump speed is to precisely control the speed of the roller operation, so as to achieve accurate flow control. The speed control of peristaltic pump is generally achieved by controlling the speed of the driving device, and the common driving devices are frequency converters, servers and stepper drivers. These driving devices can adjust the running speed of the roller through the given control signal, so as to realize the control of the rotational speed of the peristaltic pump.

The control of peristaltic pump speed has been widely used in many industrial fields. First of all, the precise control of peristaltic pump speed can achieve accurate control of the flow of the conveying medium. In some processes that require strict flow control, peristaltic pumps are widely used, such as chemical, pharmaceutical and other industries. Secondly, the control of peristaltic pump speed has certain safety significance. By controlling the rotational speed of the peristaltic pump, excessive or insufficient transmission medium can be avoided, thus ensuring the safe operation of the production process. In addition, the control of peristaltic pump speed can also extend the life of the peristaltic pump and reduce maintenance costs.

In the control of peristaltic pump speed, there are many factors to consider. The first is the choice of drive device. The drive device required by different processes may be different, and the appropriate drive device needs to be selected according to the actual situation. The second is the design of the control system. The control system needs to be able to obtain the working state of the peristaltic pump and the flow of the conveying medium in real time, and adjust the speed according to the needs. Finally, the parameter setting of peristaltic pump. Different peristaltic pump parameters have different effects on the control of speed, so it is necessary to set reasonable parameters. Taking these factors into account, the precise control of peristaltic pump speed can be achieved.

To sum up, the control principle and application of peristaltic pump speed is a complex problem involving many aspects. Through the comprehensive consideration of the driving device, the control system and the parameters of the peristaltic pump, the precise control of the rotational speed of the peristaltic pump can be achieved, so as to meet the requirements of different processes and ensure the safe operation of the production process and the stability of product quality.