When purchasing peristaltic pump, the management of enterprises will take into account a very realistic problem, the price of peristaltic pump is higher than the ordinary plunger pump. So what's the reality? Today, we will analyze the price of peristaltic pump from the maintenance and life cycle of these two points.

When purchasing peristaltic pump, the management of enterprises will take into account a very realistic problem, the price of peristaltic pump is higher than the ordinary plunger pump. So what's the reality? Today, we will analyze the price of peristaltic pump from the maintenance and life cycle of these two points.

Compared with other traditional positive displacement pumps, the initial investment is higher, but the probability of replacing parts in the actual production process of the traditional positive displacement pump is very high. According to the three-year life cycle of a peristaltic pump, a positive displacement pump needs to be repaired 5-10 times on average during this period, which does not include replacement parts, maintenance costs and other costs.

In a peristaltic pump, the pipe or hose is the only wet component, with little maintenance and no expensive seals to replace, no check valves to clog, and no rotors or stators to wear. Of course, hoses or tubes need to be replaced regularly. Even so, industrial grade peristaltic pumps can operate reliably for thousands of hours before hose fatigue fails. The hose replacement process took less than an hour, and in some cases just minutes. In addition, the hose can be changed quickly and safely without any special tools.

This is much less than the 4-6 hours of repair time required for diaphragm or single-screw pumps, not including the extra time they take up when moving, transferring, and reinstalling. Hose costs are very low compared to diaphragm or single-screw pump repairs, where wet-end replacement components (e.g., ball valves, rotors, and stator) can account for up to 75% of the initial purchase cost of the pump.

In addition, the peristaltic pump in the installation process does not need other auxiliary equipment and accessories. Diaphragm pumps require a backpressure valve and an exhaust valve to ensure proper operation of the internal check valve. Single-screw pumps typically require dual mechanical seals, a flushing system, dry run protection, and a built-in check valve. With peristaltic pumps, the cost of these auxiliary components can be waived.

Finally, many positive displacement pumps require the additional purchase of a separate control panel or frequency converter for variable flow metering. If you need to increase the flow range, the cost and complexity will increase. However, the peristaltic pump itself has a high flow range, closed-loop speed control capabilities, and extensible I/O interfaces for connecting to DCS, SCADA, and PROFIBUS systems.

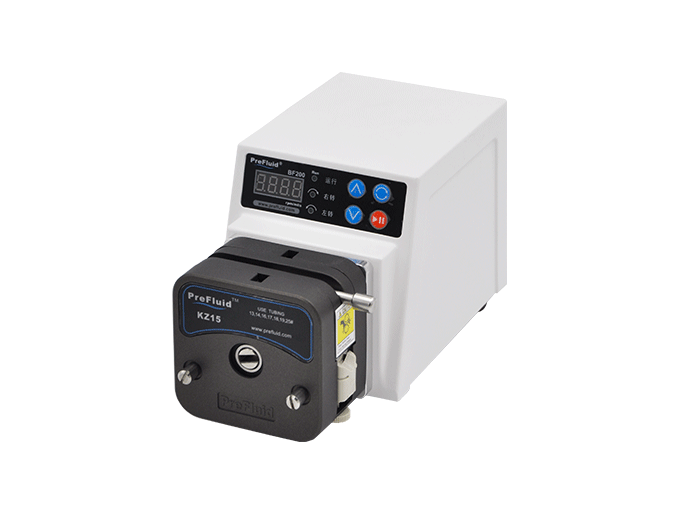

Purui fluid long-term focus on peristaltic pump, constant flow pump, hose pump, metering pump research and development, production, sales, to provide all kinds of enterprises with professional peristaltic pump solutions, welcome customers to inquire.