In the laboratory, filling, chemical production, experimental testing or chemical analysis environment, it is often possible to use corrosive media fluid transport. Improper operation may cause personal injury or device damage during transportation or dripping. Is a major challenge to safe production.

And corrosive liquid is very strict on the accuracy, the slightest mistake will affect the experimental data and final results. Therefore, the corrosion resistance and fluid accuracy of peristaltic pump in these aspects are also very high requirements.

So how does the peristaltic pump solve this problem?

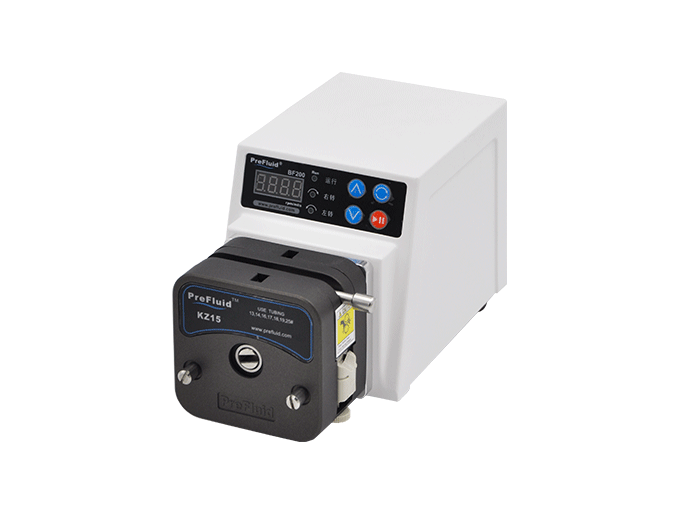

To move liquids from one container to another, this is our peristaltic pump, used for filling, repackaging and metering in a variety of industries. Different materials and specifications of peristaltic pump hose used in corrosive liquid transportation of different properties and flow requirements of liquid transportation.

In order to prevent chemical reactions and deal with corrosive liquid problems, the peristaltic pump will be precisely controlled and measured during operation, so as to achieve accurate control of the liquid. The minimum unit can be microliter measurement, accuracy is guaranteed.

The hose material can be customized, special, corrosion resistant, corrosion resistant, stable structure, no chemical reaction with the transmission medium.

Independent pipe sealed vacuum transmission, to ensure the personal safety of operators, ensure that pump components are not damaged, save maintenance costs.