The flue gas usually contains O2, CO, NO, NO2, NOx, s O2, NH3 and other types of flue gas. The gas analyzer is equipped with a high power Peltier gas cooler and a peristaltic pump for electronic detection of condensed water.

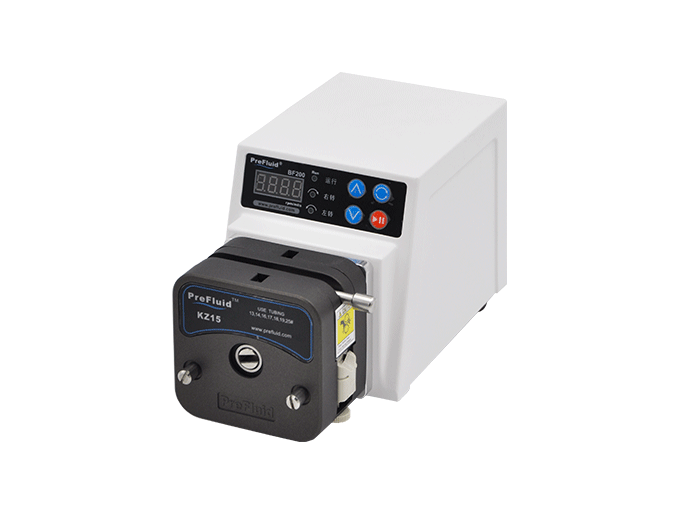

The flue gas usually contains O2, CO, NO, NO2, NOx, s O2, NH3 and other types of flue gas. The gas analyzer is equipped with a high power Peltier gas cooler and a peristaltic pump for electronic detection of condensed water. When the discharge limit is reached, the peristaltic pump automatically starts to discharge condensate water, which is very suitable for wet flue gas monitoring and analysis.

Automatic gas monitoring systems need to condense the gas before it enters the gas analyzer, separate the gas from water, and expel the condensate through a peristaltic pump. This can prevent excessive humidity in the flue gas analyzer and many components caused by corrosion.

Gas monitoring must ensure the tightness of the monitoring system. Therefore, the condensate drainage system is required to have good sealing performance to prevent outside air from entering the condenser through the drainage system and affecting the gas composition of the sample.

The chemical composition of condensate is complex and corrosive. When pre-sampled gas filtration is not effective, condensate water also contains solid particles. Therefore, it is required that the condensate drainage system has good corrosion resistance and is suitable for abrasive fluids.