The peristaltic pump is a type of pump commonly used in the industrial field. In a variety of industrial applications, hose pump peristaltic pumps are favored for their superior performance. They are not only highly reliable and durable, but also play an important role in various fluid handling processes. This article will introduce the principle, structure, application fields and advantages of peristaltic pump in detail to help readers better understand and understand this pump product.

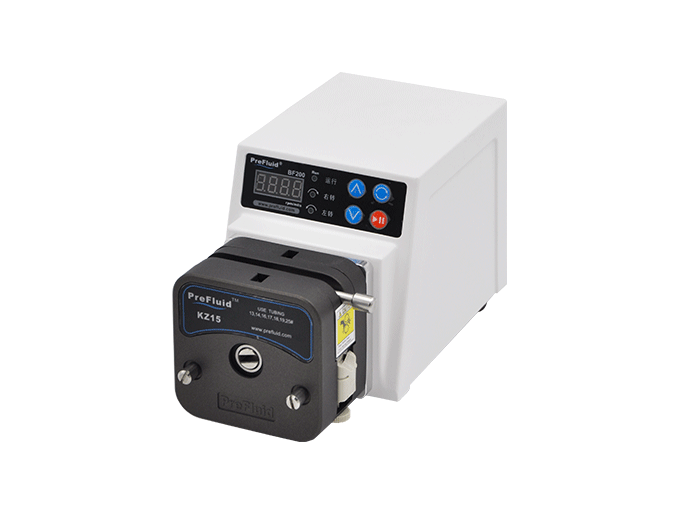

The principle of peristaltic pumps is based on the working mode of peristaltic or pumping. It is mainly composed of pump head, hose and driving device. Pump heads are usually made of metal or plastic materials and have excellent corrosion resistance. Hose is an important part of the pump, responsible for conveying fluid, and through the process of compression and release to complete the pumping work. The driving device can be a motor, pneumatic device, or other type of energy source to provide the motion force of the pump head.

Peristaltic pumps have many advantages that make them widely used in different fields. First, they are suitable for a variety of fluids, including high viscosity, corrosive, high particle content media. Secondly, the hose pump peristaltic pump provides fluid handling at a constant and precise flow rate, ensuring the stability of the production process. In addition, they have good self-priming capacity and resistance to dry operation, which is suitable for unstable fluid transport.

Peristaltic pumps have a wide range of applications. In the chemical industry, peristaltic pumps are often used to transport acids, alkalis, solvents, polymers and other corrosive media. In the food and beverage industry, hose pumps peristaltic pumps are used to stir, add syrup, transport berries, alcohol and other fluids. In the pharmaceutical industry, the hose pump peristaltic pump is suitable for the delivery of highly effective drugs, biologics and other pharmaceutical liquids. In addition, the hose pump peristaltic pump is also widely used in water treatment, sewage treatment, mining, building construction and other fields.

The advantage of peristaltic pumps lies not only in their applicability and wide range of applications, but also in their ease of operation and maintenance. Hose pump peristaltic pumps are easier to clean and maintain than other types of pumps. Since the hose is the only part in contact with the medium, cross-contamination can be avoided by simply replacing the hose. In addition, the structure of the peristaltic pump is relatively simple, does not require additional seals, and has low maintenance costs.

In short, as an important industrial pump products, the peristaltic pump has a wide range of application prospects and outstanding performance advantages. Its application in chemical, food, pharmaceutical, water treatment and other industries is more and more extensive. In the future, with the continuous progress of technology and the growth of market demand, the hose pump peristaltic pump is expected to show its excellent function and application value in more fields.