In industrial production, peristaltic pump is a very important tool. Due to some of its special properties, peristaltic pumps have a wide range of applications in different industries, such as food processing, pharmaceutical manufacturing, chemical industry and other fields. Different industries need different peristaltic pump models.

In industrial production, peristaltic pump is a very important tool. Due to some of its special properties, peristaltic pumps have a wide range of applications in different industries, such as food processing, pharmaceutical manufacturing, chemical industry and other fields. Different industries need different peristaltic pump models. This article will introduce the characteristics and common application scenarios of different peristaltic pump models in detail, so that readers can better understand the difference between different models and how to correctly select.

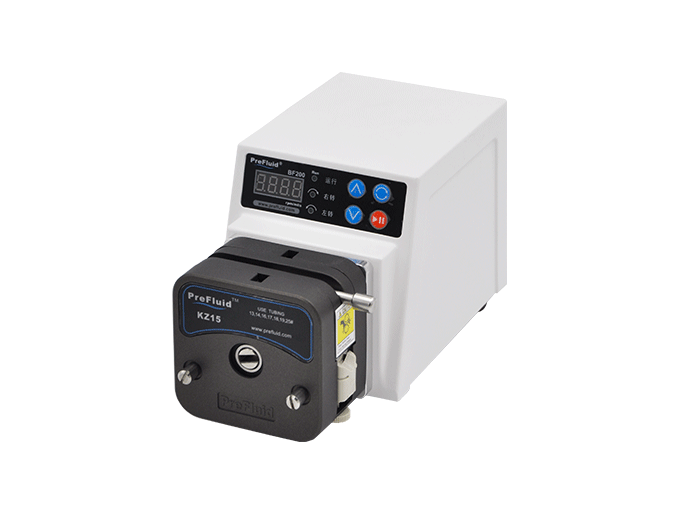

First, standard peristaltic pump

Standard peristaltic pump is a kind of pump produced by absorbing negative pressure in the residual chamber and making the hose naturally compressed. The main features of this peristaltic pump are: stability, small vibration, easy maintenance and so on. Because the standard peristaltic pump has these characteristics, it is widely used in many fields. For example, in the chemical industry, it is often used to transport volatile liquids, nourishing enzymes, etc.

Two, high viscosity peristaltic pump

High viscosity peristaltic pump is a pump suitable for conveying viscous liquids. The main characteristics of high viscosity peristaltic pump are: high pressure and large flow rate. This peristaltic pump design is special, can deal with large flow, high viscosity and other situations. High-viscosity peristaltic pumps can be seen in many industries that need to transport high-viscosity liquids. For example, chemical, adhesive, jam and other industries must use this high-viscosity peristaltic pump to achieve the desired effect.

Three, compression peristaltic pump

Compression peristaltic pump is also called "double channel pump". The characteristics of the compression peristaltic pump are: there is no gear, belt, coupling and other connecting devices between the pump body and the drive, simple structure, stable performance, easy to use and maintain, and there will be no leakage and other problems. The main advantage of this peristaltic pump is that it can work under high pressure and strong corrosion environment. Compression peristaltic pump has been widely used in chemical industry, medicine, glass and other fields.

Four, stainless steel peristaltic pump

Stainless steel peristaltic pump is a reliable conveying equipment, and has the characteristics of stainless steel, suitable for conveying a variety of chemicals, diet and other liquids. Stainless steel has high corrosion resistance, good performance for high temperature, high pressure and corrosion resistant media, and is widely used. Its efficient and stable performance advantages make the use of stainless steel peristaltic pumps increasingly common in pharmaceutical, beverage, food, paper and other fields.

In short, the choice of peristaltic pump model should be based on the needs of actual application scenarios. Different peristaltic pumps have different characteristics and application scenarios, and the performance of the product itself determines its advantages in actual operation. If used properly, the peristaltic pump is a very powerful conveying equipment that can play a huge role in various industries.