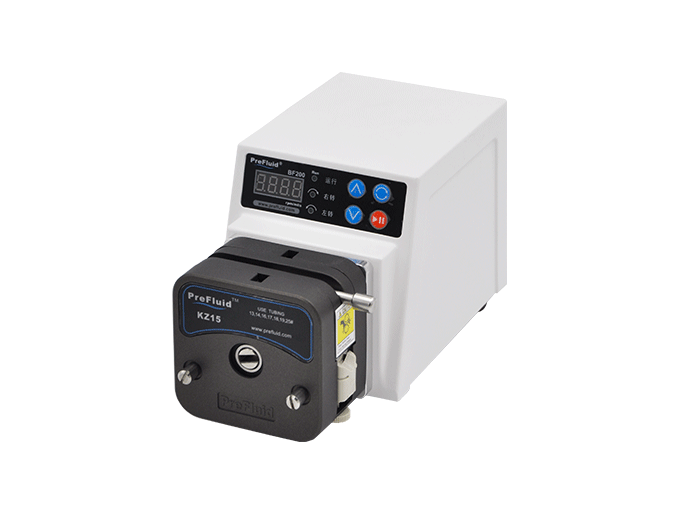

Peristaltic pumps use rotary rollers to squeeze the hose to transport liquid. Because the liquid only flows into the hose, no contact with the pump head, no cross contamination, high conveying accuracy, small shear effect, widely used in chemical industry, environmental protection, scientific research, pharmaceutical, beverage, food, printing and other fields.

The peristaltic pump consists of a drive, a pump head and a peristaltic pump silicone tube. The fluid is isolated from the pump tube, the pump tube can be quickly replaced, the fluid can be retrograde, the operation is dry, the maintenance cost is low, and the pressure is small, which constitute the main competitive advantages of the peristaltic pump.

The flow regulation of the metering pump is to drive the rotation of the adjustment screw by rotating the adjustment handwheel, so as to change the distance between the arch connecting rod and change the moving stroke of the plunger (piston) in the pump chamber to determine the size of the flow rate. Adjust the scale of the handwheel to determine the plunger stroke. The accuracy is 95%. The pump has excellent performance. Among them, the diaphragm metering pump absolutely does not leak, high safety performance, accurate metering transmission. The flow rate can be adjusted from zero to a large rating range, and the pressure can be adjusted from normal pressure to a large allowable range