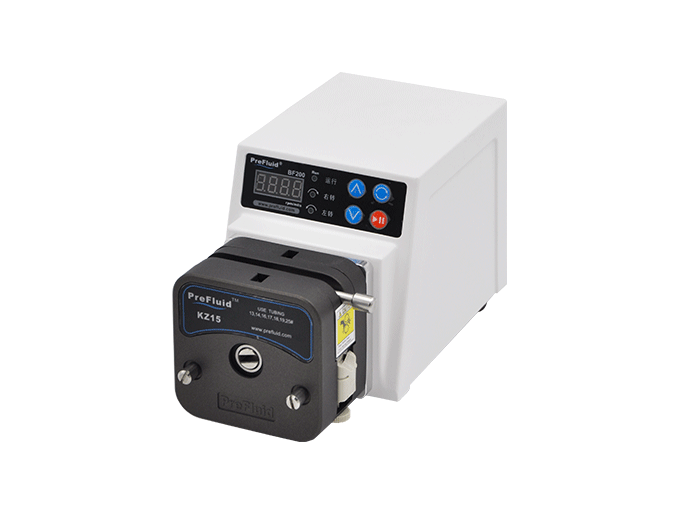

In some industries, when using fluid transfer equipment, peristaltic pumps are often used, and the pump consists of three parts: the drive. Pump head and hose. The liquid is transmitted through a hose and can be retrograde. Dry operation and maintenance costs are low, which is why it is very popular. Although the pump is easy to use, many customers do not know how to improve the efficiency of the pump. The following PRy fluids will explain to you:

1. The pump relies on a compression hose for fluid flow. Transmission. When the pump is not working, the press block can be loosened so that the hose is in a natural state of non-compression, thereby extending the service life.

2. When selecting pump parameters, the theoretical flow rate is greater than the actual flow rate, generally greater than 30%. Because the pump tube is soft, the negative pressure and discharge pressure are small. If the liquid transported has a certain viscosity or the pipe has a certain length, part of the actual flow rate. Therefore, in order to achieve the required flow, the theoretical flow rate is slightly higher than the actual flow rate.

3.

Peristaltic pump hose is divided into imported hose and domestic hose. Due to the high damage to the pump head hose, it is necessary to have good compression elasticity and tear resistance, and a special hose can be used to save hose replacement time and increase the working time of the pump.

4. When using the equipment, pay attention to cleaning the debris on the pump body and hose. Since the peristaltic pump is a precision instrument, it mainly relies on the press roller to squeeze the hose. If the incoming liquid sticks to the press roll and the press block due to hose damage, it will change the compression clearance of the pump head. Even if the change is small, the hose can be damaged prematurely, affecting the use of the pump.

5. Under the premise of meeting the flow rate, the pump speed can be reduced to less than 300 RPM. The flow of the pump is determined by the speed of the pump wheel. If the rotation is too fast, the hose loss will increase. Therefore, you can choose a pump with a larger diameter to reduce the speed of the pump.

6. The pipe inlet should be as short as possible, and the joint and diameter of the pipe should not be lower than the diameter of the stuck pipe installed in the pump head. The suction of the pump is caused by the rebound of the pump pipe. If the pipe, especially the inlet pipe is too long or small in diameter, the suction end resistance is too large, and the resistance is too large to block the rebound of the pump pipe, resulting in actual flow loss. Similarly, if the outlet pipe diameter is small or the pipe is too long, because the discharge pressure of the pump is generally small, when the discharge resistance is too large, the derived flow rate will be reduced.

7. When using the pump, the hose should be checked regularly for damage. Because the hose is a wearing part, once damaged, it will lead to liquid leakage. Therefore, it is necessary to check regularly.

8. When choosing peristaltic pump, pay attention to whether the liquid transported will corrodes peristaltic pump hose. Due to the wide variety of liquids to be delivered, no single hose can withstand every liquid, so you need to determine your own liquid type and consult a PRy fluid technician to choose.

These are some of the ways to improve the efficiency of peristaltic pumps, if you need technical support, you can contact PRy Fluid technicians.