The characteristics of the silicone tube imported from the peristaltic pump: the conveying medium is not in contact with the pump body, which is conducive to transporting some highly corrosive media to the metal, such as various acids, alkali solutions or salt solutions containing chloride ions. The silicone tube imported from peristaltic pump is mainly used in laboratory, suitable for multi-pump head series, especially with DG series pump head, to achieve multi-channel, small flow liquid transmission. The BT 10-1L driver can output high torque and provide a flow range of 0. 02≤50(ml/min). Large-screen dot-matrix LCD displays are used for menus and parameter setting menus. Simple and intuitive display of flow and speed on the same screen, user-friendly interface. It has a flow correction function, which can be corrected when the flow deviation occurs to meet the user's requirements for flow accuracy. The multi-channel peristaltic pump has a variety of control methods, which can be controlled externally by standard external control interface and RS 485 communication interface.

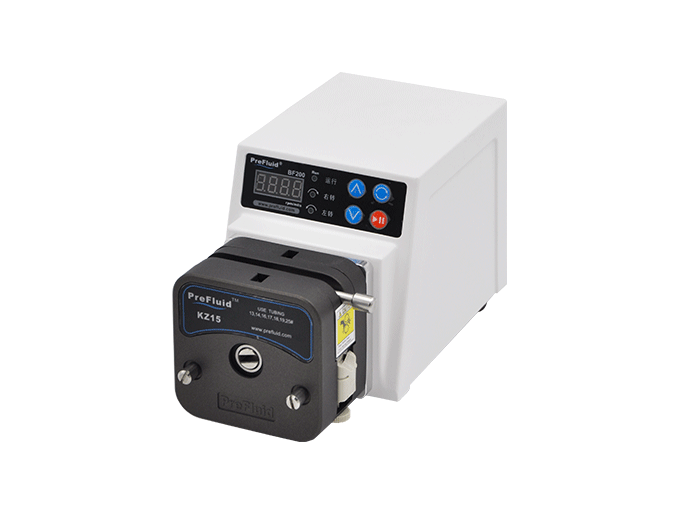

The working principle of the peristaltic pump is very simple. The structure of peristaltic pump consists of three parts: peristaltic pump driver, peristaltic pump head and peristaltic pump hose.

Peristaltic pump is a new type of industrial pump, is the product of modern industrial development, widely used in medicine, food, chemical and other industries, it transport medium high sensitivity, high viscosity, corrosive, abrasive, high purity requirements and some granular materials.

Chemical stability:

1. Resistance to weak acid and base, such as: weak corrosion products, low concentration potassium permanganate, acetaldehyde reagents, animal oil, vegetable oil, Vaseline, glucose, alcohol, hand sanitizer, juice, blood, weak acid, alkaline gas, etc.

2. It is not suitable for high concentration sulfuric acid, hydrochloric acid, sodium hydroxide, nitric acid, lubricating oil, silicone oil, mineral oil, gasoline, diesel oil, hydraulic oil, high concentration acetone, carbon tetrachloride, high concentration ozone and other strong acids and bases and organic solvents.

3. Can work in the working environment of -50≤200 degrees, can use ethylene oxide

Features: high purity imported silicone rubber raw materials platinum vulcanization vertical extrusion molding, smooth inner cavity, long-term extrusion inner wall non-stick, dimensional tolerance accuracy, uniform wall thickness non-eccentric, high wear resistance, high rebound rate, can meet food hygiene, pharmaceutical iodine, medical testing standards.

Wear resistance: adjustable peristaltic pump speed and flow, peristaltic pump silicon tube ultimate test life of 300 rpm/min, transport medium for water, continuous service life of 500 hours, platinum silicon tube made of other imported materials than other imported materials durable 5 times.

In the whole peristaltic pump system, the hose is commonly used consumables, and accordingly there will be many problems...

Mar 09, 2023 Read Details

How to calculate the flow rate of peristaltic pump? The peristaltic pump head can be assembled with multiple pump tubes,...

Jun 27, 2023 Read Details

A peristaltic pump is a very common type of pump that is expected to pump liquid into the pipe and expel it. In some app...

Mar 15, 2024 Read Details