Peristaltic pump is a new type of industrial pump, in pharmaceutical, food, chemical and other industries used to transport with sensitive, viscous, strong corrosive and containing a certain granular material medium.

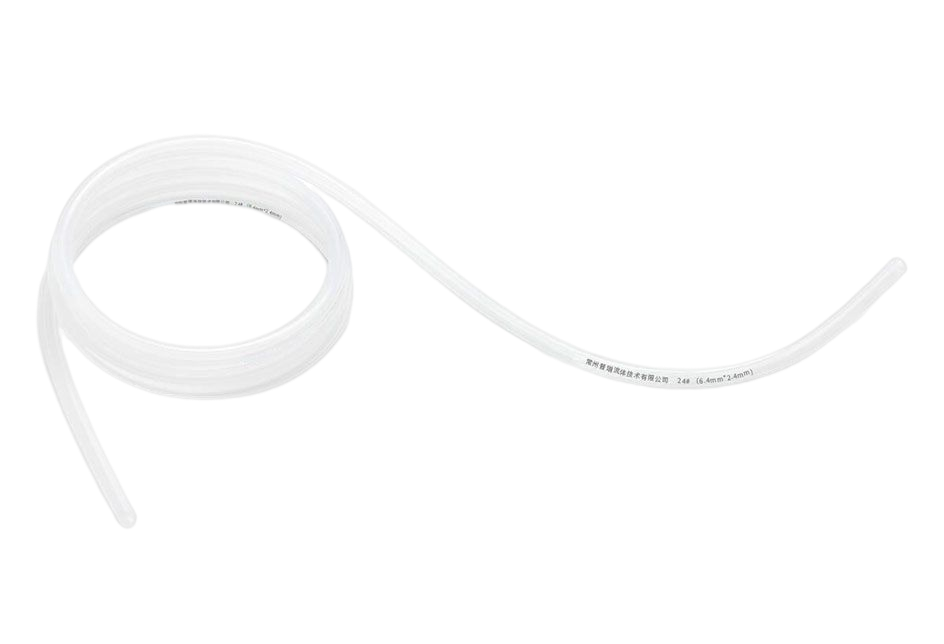

Peristaltic pump system composition: peristaltic pump system is composed of three parts: peristaltic pump driver, peristaltic pump pump head, peristaltic pump pump tube.

So how to reduce the pulsation of the peristaltic pump? The manufacturer of Peristaltic pump is introduced from the following 5 aspects:

1. Choose a thinner hose at the same flow rate: with a thin tube, the smaller the flow rate, the smaller the pulsation amplitude.

2, the use of pulse damper: using the principle of air compression, absorb the pulse.

3, increase the number of rollers: increase the frequency of pulsation, reduce the amplitude of pulsation.

4, adopt two pump heads, roller staggered Angle: use pulsation cross complement to eliminate pulsation.

5, the use of back pressure: output tension is the pump pipe deformation absorption pulsation.

Changzhou Purui peristaltic pump manufacturer sorted out the material and application fields of the above peristaltic pump pump head according to years of peristaltic pump research and development and manufacturing experience, combined with customer cases of various industries and fields served by referring to the company's product parameters, hoping to help you.