Foamed cement fully foamed ordinary cement sand paddle, so that originally dense cement inside the uniform distribution of small holes, greatly reducing the density of cement. Foamed cement has good sound insulation and noise reduction due to the reduction of pore density. Isolation vibration and other features. Due to the low density of foamed cement, the amount of cement is reduced, the weight is reduced, and the building bearing capacity is increased.

Foaming agent is used in the production of foamed cement. The precise and stable delivery of blowing agent will affect the degree of foaming. Customers used to use ordinary gear pumps on cement foam machines, but the following problems existed in the production process:

1. The conveying accuracy is poor, and the foaming rate of molded foamed cement changes greatly.

2. The amount of blowing agent is unstable, sometimes more and sometimes less, and the waste is large.

3 gear pump wear need to replace the gear, serious need to replace the pump.

4. The replacement and maintenance of the traditional gear pump is more troublesome.

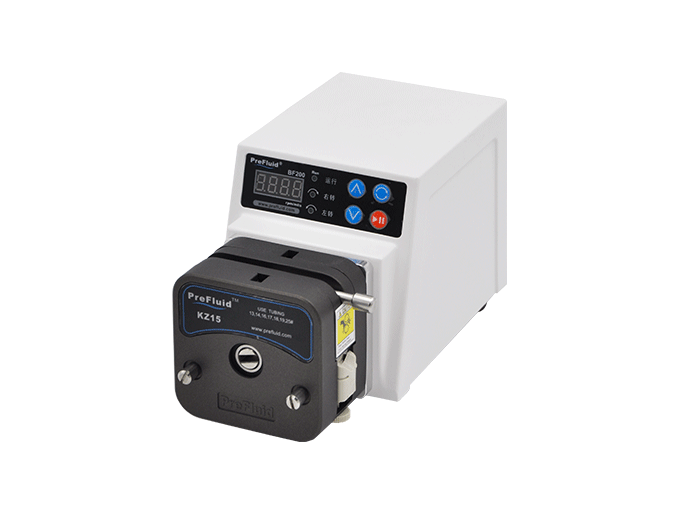

Later, the customer tried the

Peristaltic pump, and the above problems encountered by the customer in the use of the process can be well solved by the process comparison. Most importantly, with the use of the peristaltic pump, the key indicators of the foaming rate of the foamed cement produced are continuously guaranteed, improving the quality and quality of the products produced by customers. At the same time, due to the high precision and precise transportation of peristaltic pump, the waste of blowing agent is solved and the cost is saved for customers.